Main Feature of KURANODE

KURANODE is anode material classified in hard carbon, used for lithium-ion battery.

It is made from ecofriendly natural plant as raw material.

Hard carbon including KURANODE has better input and output performances,

cycle performance and low temperature performance than graphite which is broadly used as anode material.

Moreover, KURANODE has cost competitiveness and good handling property (less moisture absorption) in

comparison with traditional hard carbon.

-

Strong Benefit of

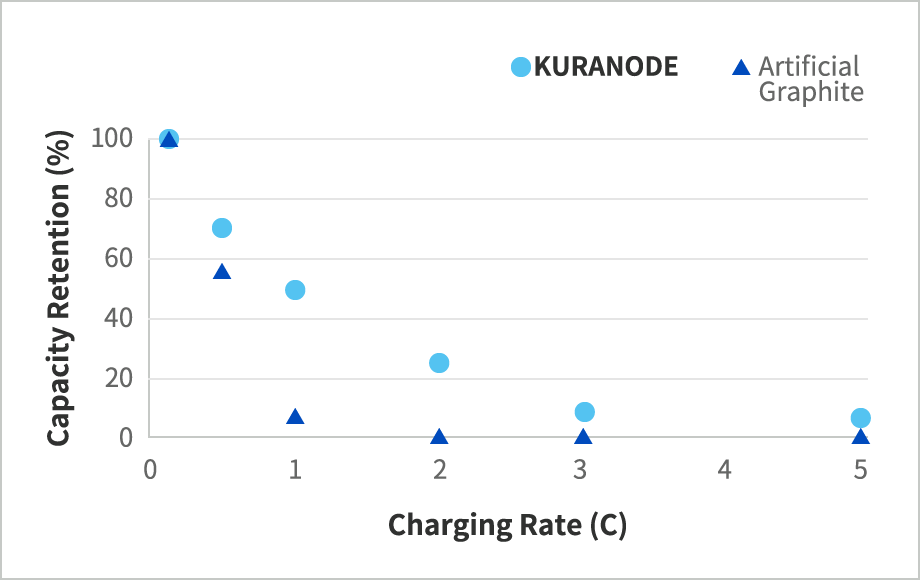

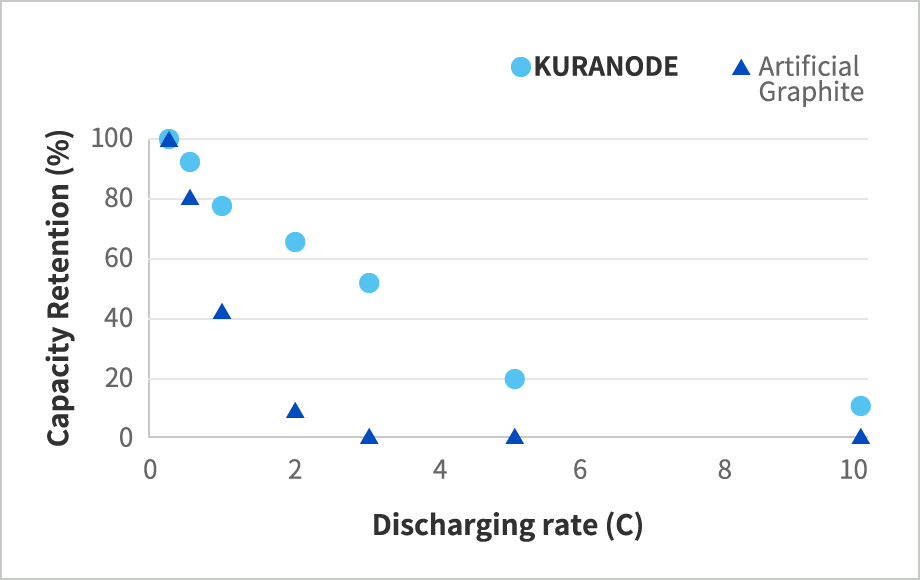

Hard CarbonInput and Output Performances

Cycle Performance

Low Temperature Performance

-

Further Benefit

Cost Competitiveness

High Moisture Resistance

(water based binder is usable)

-

1

Especially suitable for applications requiring regeneration capability

such as automobile use. -

2

Suitable for anode materials not only lithium-ion battery (LIB) but also lithium-ion capacitor (LIC) or sodium-ion battery (SIB, NaIB)

-

3

Usable with water based binder (e.g. SBR/CMC) as well as solvent based binder (e.g. PVDF) thanks to its high moisture resistance.

Low Temperature Performance

- Cathode: NCM

- Cell: Laminate type

- Measured by Kuraray

-

Charge rate property at -20℃

-

Discharge rate property at -20℃

KURANODE can

charge and discharge

even under severe conditions

(low temperature and high rate)

under which graphite

can not do.

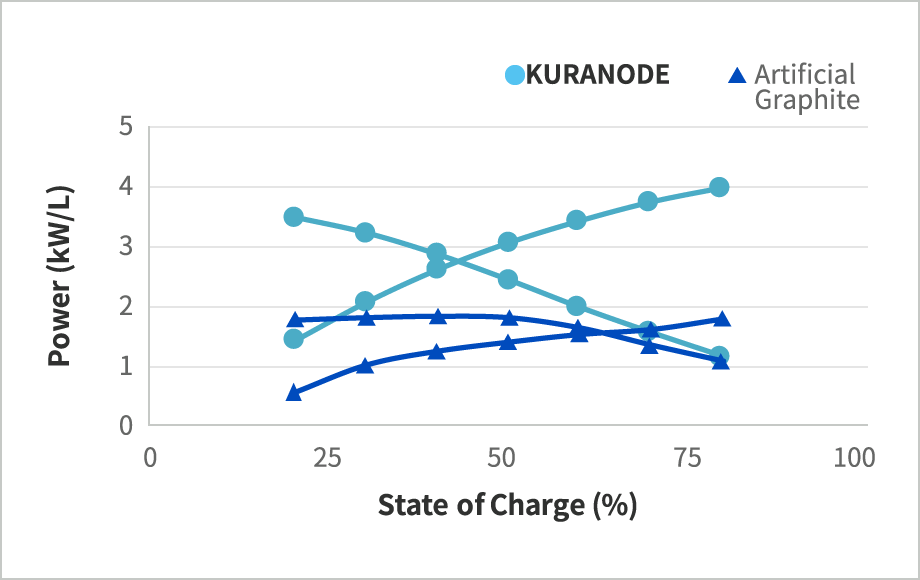

Hybrid Pulse Power Characterization

- Cathode: NCM

- Cell: Laminate type

- Temperature: 25℃

- Plotted maximum input/output pulse power for 10s of each SOC

- Measured by Kuraray

-

-

Input and Output

Performances

are superior

to graphite which is commonly

used as anode material.

Grade/Properties

| Grade | Type1 | Type2 (9μm) |

Type2 (5μm) |

|

|---|---|---|---|---|

| Average Particle size D50 | μm | 9 | 9 | 5 |

| Specific Surface Area | m2/g | 4 | 4 | 6 |

| Interlayer spacing d002 | nm | 0.38 | 0.38 | 0.38 |

Contact

Please feel free to contact us if you need further technical information or sample.